Interview by Lula Criado

Many know Ávila as a small medieval town in the west of Spain known worldwide for its iconic Romanesque walls. Now, Ávila will also go down in history as being home to Nagami Design, a design brand that explores the future of product design in a new technological era—founded in 2016 when architects Miki Jiménez García and Ignacio Viguera Ochoa joined forces with architect Manuel Jiménez García.

The trio got together mainly to develop VoxelChair v1.0, commissioned by the Centre Pompidou for the exhibition Imprimer le Monde. VoxelChair v1.0 became part of the Centre Pompidou’s permanent collection upon completion of the show. Since then, Nagami Design has collaborated with internationally renowned designers, artists and architects, such as Davide Quayola, Zaha Hadid Architects, Ross Lovegrove, and Daniel Widrig.

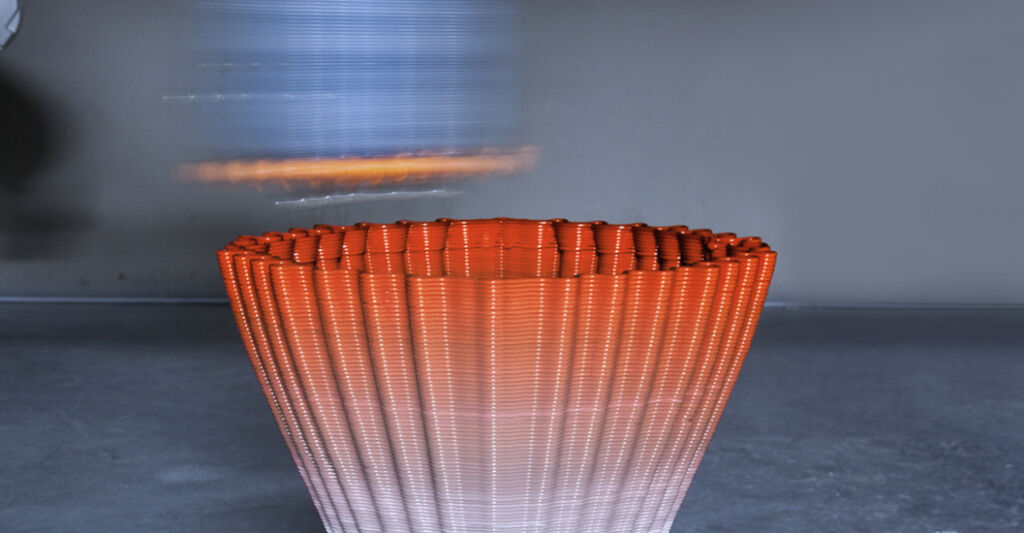

Nagami Design aims to explore new and sustainable territories, bridging imagination and creation. Their practice involves developing software that will bring to life works of 3D printing, computational design, and robotic manufacturing. They debuted during Milan Design Week 2018 with the presentation of four chairs: Bow and Rise by Zaha Hadid Architects, Robotica TM by Ross Lovegrove, and Peeler by Daniel Widrig.

These chairs are the result of extensive research into material experimentation and fabrication. Bow and Rise were printed with PLA plastic, a biodegradable material derived from renewable sources such as corn starch. As a result, the design of Robotica TM mimics the natural programming or development found in nature. In contrast, Peeler was designed to satisfy the ergonomic requirements of the human body and was manufactured via a process which minimised by-product waste.

Aside from the chairs above, Nagami Design has also created an oversized prototype for Canaria Ltd as part of the 2016 NASA Space Apps Challenge. When looking to the future, Nagami told us they are expanding their facilities but keeping the company’s core focus on researching new printing methods. From extruding materials at impossible angles to [creating] colour gradients that were unachievable before, these [chairs] reflect our passion for technology and design and our constant search for new challenges to create objects we’ve never seen before.

For those unfamiliar with Nagami, who is behind the studio and what led you to found Nagami?

Nagami is a Design brand and robotic manufacturing startup based in Avila, Spain. The company was created in 2016 mainly for the development of VoxelChair v1.0, commissioned by the Centre Pompidou for the exhibition “Imprimer le Monde”, which took place in Paris in March 2017.

Marie-Ange Brayer and Olivier Zeitoun, curators of the exhibition, approached the Architects Manuel Jimenez Garcia and Gilles Retsin (co-directors of the Design Computation Lab at UCL – The Bartlett School of Architecture) to develop a new prototype of their robotic spatial 3D printing method. Miki Jimenez Garcia and Ignacio Viguera trained Architects in Spain, had already started a digital prototyping company and decided to join forces with Manuel in funding a robotic manufacturing startup to support the fabrication of the prototype for the Centre Pompidou.

The company’s short-term goal was to develop a more robust and efficient robotic extrusion method. In the long term, Nagami would start to use this method to build their 3D-printed furniture and medium-scale Architectural products.

VoxelChair v1.0 became part of the museum’s permanent collection at the exhibition’s completion. Manuel, Miki, and Ignacio continued developing the technology and creating products specially designed for their manufacturing method. As a result, Estrat Chair, Nital Vase, and Nobu Chair are the first furniture pieces produced by the company. Nagami also participated in projects collaborating with other companies, such as Canaria, with a project supported by Nasa Extreme Tech Challenge.

Nagami presented a pioneering project at Milan Design Week 2018, combining computational design and large-scale robotic 3D printing — Brave New World: Re-thinking Design in the New Age of Technology. It will be officially launched with the presentation of four chairs made in collaboration with Zaha Hadid Architects, Ross Lovegrove, and Daniel Widrig. Could you tell us more about these innovative collaborations?

After testing our technology with our products, we wanted to open this method to those who could challenge it and develop new ideas around 3D printing on a large scale. We’ve known the three designers involved in this project for a long time. We have shared discussions, lectures and other events, mainly linked to the London Architecture and Design scene.

For Milan Design Week, we needed to work with people we trust and admire. The three designers in the show always deliver high-quality design and innovation in every project, and they share our love for design and attention to every detail. This technology suits their formal expression, design sensibility, and passion for products that couldn’t have come to life with traditional manufacturing methods.

Ross Lovegrove, Patrik Schumacher, and Daniel Widrig have been excited about the project. They have delivered high-quality designed objects, a high commitment to the project, and constant support to the company. Their involvement in the event goes beyond this project, and we are excited to create more products together after Milan.

What were the most significant challenges you faced while developing these pieces?

The entire project has been a challenge from the beginning. The company is built on bringing objects that couldn’t exist before to life. Making the impossible requires hard work, commitment, and a passion for design that prevents you from trying when everything seems unachievable.

We have been involved in digital fabrication and robotics for the last five years, developing research projects in workshops and exhibitions. Academic and artistic projects are excellent platforms for testing innovative methods, but evolving those methods towards commercially viable products is a real challenge.

3D printing reduces the production chain, allowing designers to materialise their prototypes quickly without the tedious fabrication of parts, shipping, and complicated assemblies. However, the use of this technology is mainly limited to the production of small-scale objects. Desktop 3D printers are slow and expensive about the volume that they can print. These are some reasons why large-scale 3D printing is usually just present in exhibitions and luxury objects.

Nagami’s founders aimed to bring the formal freedom of 3D printing to a larger public. This required the development of an efficient technology that could reduce manufacturing costs and speed up the printing process without compromising design quality.

We are developing limited editions, such as Zaha Hadid Architects’ Bow and Rise chairs, which establish new arenas for innovation that are applied to more products. However, we are also offering products that are accessible to a much larger group of design lovers. Some of our products are faster and cheaper to print than the 1/6 scaled version of the same piece printed in a desktop 3D printer. This opens up new frontiers for product design, where broadly distributed 3D printing objects can become a reality.

Each one of the pieces on the show has intense research behind it. We’ve developed custom methods for manufacturing these chairs at high quality with the designers. From extruding materials at impossible angles to creating colour gradients that were unachievable before, these products reflect our passion for technology and design and our constant search for new challenges to create objects that we’ve never seen before.

It is common to think that digital manufacturing offers the possibility to materialise without much effort, but that is far from the truth. We produced an endless amount of prototypes until we managed to achieve the desired quality of these products. Each of them has been very carefully crafted both digitally and physically.

Research and innovation are at the core of Nagami’s projects, developed in collaboration with renowned architects, designers and artists. So what are the top trends (or innovations) that might reshape the future?

We believe that construction will become one of the following areas of innovation, mainly at the scale of Architecture. The low productivity of the construction industry and its slow evolution rate is anticipating a radical change in design-related disciplines.

Different media have already anticipated a coming construction revolution, situating construction as the next industry to be automated. However, it does not make sense that we are building the same way as 50 years ago, which situates construction as a vast area for innovation and application of new technologies.

Architects and designers are starting to take automation as one of the main drivers when designing objects of various scales, from furniture to Architecture. In addition, Digital manufacturing technologies, such as 3D printing, contribute to creating more sustainable and safer environments.

We think that the times when construction required a large variety of pieces made by multiple manufacturers, later shipped on-site for complicated assemblies, putting workers in unsafe situations, are very soon coming to an end. These technologies will also contribute to the much more efficient use of materials, avoiding the necessity of formwork and scaffolding. This will lead to a considerable reduction in waste.

What directions do you imagine taking Nagami’s work in?

On the one hand, we are starting to increase productivity after the long phase of product development to get the first edition of our pieces ready for Milan. On the other hand, we can’t stop innovating in our products, and we are already planning new research threads for new collections.

This will include pieces printed by two/three robots simultaneously, which will allow materialising previously unachievable geometries. We are expanding our facilities but keeping the company’s core focus on researching new printing methods. We aim to create incredible design products and work on larger projects like 3D-printed architectural scale products.

What is your chief enemy of creativity?

I am building the unseen without making it inaccessible.

You couldn’t live without…

Apart from chocolate… We couldn’t live without each other. Nagami’s team is assembled based on trust and passion for design, and this initiative will never work without each of us giving all our energy to it.