Text by CLOT Magazine

BIOFABRICATE is the annual conference that brings together critical thinking and design to challenge both what we know and how we use materials. The conference was founded by designer and TED Senior Fellow Suzanne Lee in 2014 and is focused on creating a better sustainable future in harmony with our environment. Suzanne Lee is also the founder of Biocouture™, an innovative and pioneering living materials consultancy focused on growing materials from living microorganisms.

The central axis of this year’s BIOFABRICATE summit, hosted by Parsons School of Design (New York City), lay at the heart of emerging grown materials and the role biotechnology has in shaping a new industrial revolution. From disciplines ranging from architecture, design, fashion and furniture to health and beauty, international speakers shared their disruptive ideas and thought-provoking projects.

Divided into four sessions, the programme included keynotes and panels from thinkers and academics, like Professors Anthony Dunne and Fiona Raby, to founders and CEOs of some of the most innovative startups —Ecovative, AMSilk, bioMASON and Living Ink Technologies— and artist and designers such as Tina Gorjanc, Maurizio Montalti, Heather Dewey-Hagborg, Christina Agapakis and Amy Congdon.

Professor of Design and Emerging Technology at Parson School of Design Anthony Dunne inaugurated this year’s edition with the keynote Design Boundaries: what role for design in biotech? Dunne made two important observations. Firstly, he pointed out that critical design is not only about design as a means to make products but also it is a way to start a conversation. Secondly, he remarked how speculative design projects have the danger of being misinterpreted when they reach a lay audience. Journalists shouldn’t forget that, in most cases, these projects are intended to spark debate and critical thinking using design as the means, not just for designing a particular new utilitarian object.

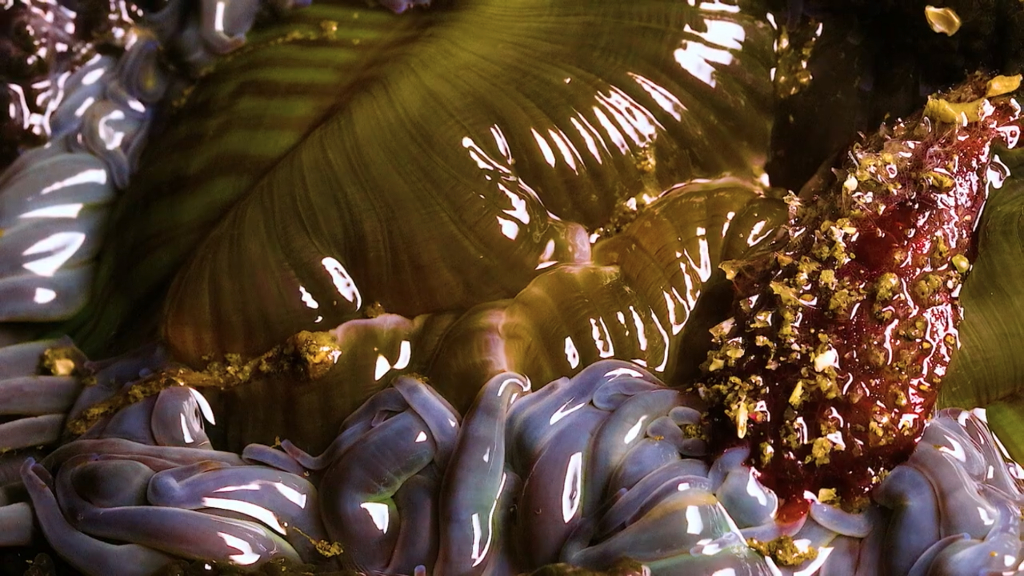

At the Design Lab Exhibition, attendees learnt from platforms such as BiotA Lab and projects such as Spiderwort, Amino Labs, Living Ink, and Fragrant Moss; all are accelerating the future. From prototypes to speculative investigations, artists and researchers are looking into nature to find new ways to develop and create materials and textiles that are beyond traditional manufacturing. The discussion panels were not only focused on the design and technical aspects; there was a lot of discussion around social, cultural and ethical aspects of the role of the design in biotech and about the implications of manufacturing with living materials such as human DNA.

Three interesting projects presented during the conference that are challenging our conceptions about manufacturing were Pure Human (by Tina Gorjanc), Bioesters, and Spiber Inc. Three projects that take as raw material human DNA, plant molecules and animal proteins, respectively, to reshape our understanding of what material design is. Designer Tina Gorjanc’s beliefs are at the core of social responsibility, ethics, and sustainability, with a critical approach to designing products and systems. Apart from participating in the session Biological Boundaries: public understanding, technology access & genetic ownership and the panel What rights to our genetic information? Gorjanc presented her project Pure Human, a speculative project focused on addressing concerns and generating debate on the protection of human genetic information.

Bioesters, founded at FIT in New York City, work at the intersection of biology and 3D printing to create biodegradable filaments made of alginate that can be treated like yarn and knitted into textiles. Last but not least, Spiber Inc. showed their spider protein-based material made of 20 types of amino acids that allows them to produce endless variations of materials with a positive impact on society. These three different points of view are actively questioning what we know about textiles and materials.

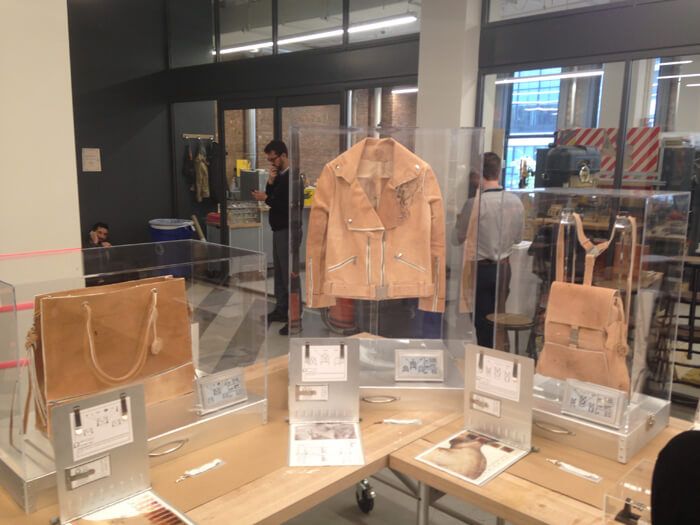

BIOFABRICATE 2016 closed with two worldwide presentations following the last session Lab to Street: crafting the future. In the first one, adidas launched their new projects for the new division ‘Futurecraft’, presenting two new projects. First of all, the collaboration with Parley for the Ocean, an initiative to clean the Maldives seas. They designed a pair of trainers where the upper is made with fabric obtained from plastic removed from the polluted waters around the islands. Importantly, this new fabric is fully biodegradable. To build on the concept of sustainability, Adidas also presented a new trainer prototype made of Biosteel™ fibers, a new spider silk material developed by AMSilk©. Besides trainers, Biosteel™ has also been used in medical devices and cosmetics.

In the second worldwide presentation, Ecovative Design, global pioneers in the use of mycelium as a raw material and BioMASON, known for manufacturing biological cement employing microorganisms and chemical processes, joined forces to develop biofabricated furniture. They unveiled an accent table that was another of the popular presentations at Biofabricate 2016 and is literally grown using Mushroom® materials, agriculture waste, and microorganisms. The number of applications the company can target is vast: from living walls to functional furniture and wearables. Some of the materials presented here were incepted years ago, and even though progress can feel slow, we must remember how difficult it is to bring production and commercialisation together to scale ideas.

It’s important that initiatives like BIOFABRICATE bring together all these creators to exchange ideas and knowledge and to create debate and reflection, opening and creating new frontiers for a more sustainable future in which biological materials are leading a new industrial revolution. MIT chemists just have determined the structure of the enzyme polyhydroxyalkanoate (PHA) synthase, found in nearly all bacteria. This enzyme can produce biodegradable plastics, which could involve a possible step toward commercial production of biodegradable plastics. So, perhaps, we can say that we are approaching the 3rd Industrial Revolution.