Text by CLOT Magazine

The Biofabricate Summit returned for its fourth iteration this December. The annual summit brings together global leaders in the fields of design, biology, and technology to New York City to share and discuss the future of grown materials. As a living document of the development of this nascent field, this year’s edition did not fail to disappoint. From the exhibitions of synthetic leather and upcycled ocean plastic shoes to panels on symbiosis and biostrategy, the lessons shared and conversations expanded the working frontier of biofabrication.

This year’s summit occurred at New Lab in the Brooklyn Navy Yard. Fittingly, the renovated yard has served as a site for the state-of-the-art in manufacturing, historically for shipbuilding and contemporaneously as an innovation hub. We were able to experience some of this tradition in the breaks between sessions, as parts of the New Lab were opened up for a design lab, bio lab, and exhibit gallery. The access brought us up close to the change makers and products themselves.

With this new edition, Biofabricate delivered an overview of the future of new materials. The theme for the summit was set in the opening remarks of Biofabricate founder Suzanne Lee – biofabrication is shifting from academic interest to a focus on media and consumer-oriented brands. To better understand this shift, the summit was organised into five sessions: the microbiome, plastic, symbiosis, evolving materials and biostrategy. Within each session, it was evident what organisers emphasised, bringing in speakers incorporating collaboration into their practice.

The microbiome is a dynamic competition of diverse microorganisms that is influenced by individual conditions. It comprises all of the genetic material within a microbiota (the entire collection of microorganisms in a specific niche, such as the human gut). This can also be referred to as the metagenome of the microbiota (Nature Magazine).

In the first session, Microbiome: designing for health, AOBiome Chief Medical Officer Larry Weiss and Richard Beckett of the BiotA Lab at University College London gave presentations that linked bacterial ecosystems found on our bodies and in the built environment with health outcomes. Richard Beckett, an investigator whose speculative project NOTBAD (2017), is now exploring the feasibility of engineering the microbial community of the indoor built environment to rethink architecture and design buildings for a healthy microbiome.

The second session, Plastic: turning problems into solutions, emphasised applications to reduce and upcycle plastic waste products and reminded us of the shocking images captured by photographer Caroline Power between the islands Roatan and Cayos Cochinos near Honduras. The picture went viral last October, showing a blanket of plastic, bottles, and rubbish, highlighting the damage done to the planet’s oceans. Parley for the Oceans founder Cyrill Gutsch gave the session keynote on “the need to make protecting the oceans ‘good business’ or better business than polluting the ocean.”

Parley for the Oceans is the space and network where creators, thinkers and leaders come together to raise awareness for the beauty and fragility of our oceans and collaborate on strategies that can end their destruction. It has established collaborations with global commercial brands to promote their new strategy of plastic reduction AIR (Avoid, Intercept, Redesign) and use their recovered ocean plastic Parley Ocean Plastic™.

PI NASA Juno and Chief Scientist DEEP SPACE raised awareness of biofabricated products coming to the market and being cautious of creating the “next plastic”. In this sense, Mango Materials founder Molly Morse uses a class of prokaryotes that can use recovered methane gas to produce biopolymer polyhydroxyalkanoates (PHA). PHA, compared to more common biopolymers like polylactide (PLA), has the advantage of being compostable using traditional compost methods and can be easily processed to manufacture caps and textile fibres.

Symbiosis (from the Greek sumbiōsis ‘living together’) is a mutually beneficial relationship between different people or groups (English Oxford Dictionary). In this sense, in the third session, Symbiosis: collaboration driving innovation, Liz Ciokajlo (OurOwnSkin), Maurizio Montalti (Officina Corpuscoli) and Natsai Chieza (Faber Futures) addressed the necessity of incorporating disparate backgrounds in the design process.

Liz Ciokajlo and Maurizio Montalti have collaborated to produce a speculative MarsBoot. The piece, CASKIA (2017), was commissioned by Paola Antonelli, Senior Curator of the Museum of Modern Art (MoMA), for their exhibit ‘Items: Is Fashion Modern?’. The piece was also exhibited in the Design Lab. Inspired by the plastics culture of the 1970s, CASKIA recasts in original MoonBoot in a biodegradable, feminist light.

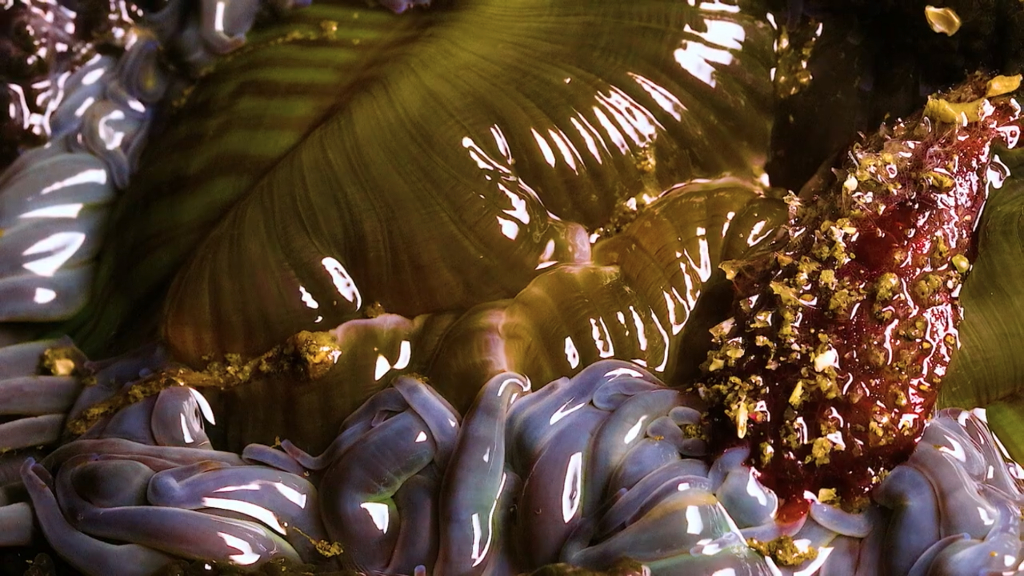

On the other hand, material design researcher and artist-in-residence at Ginkgo Bioworks Chieza spoke about bacterial pigments and collaboration as the future of design. They showed Assemblage 001 (2017), the world’s first garment dyed by Streptomyces. Chieza uses a direct fermentation process to dye directly on the fabric.

In the fourth session, Growth: evolving materials Modern Meadow CSO Gabor Forgacs, BioMASON founder Ginger Krieg Dosier, Ecovative co-founder Eben Bayer, senior material designer at Modern Meadow Amy Congdon and researcher Veronika Kapsali gave insights on bioprinting and bio-fabrication, growing materials from mycelium and yeast engineered, and, the material design. Ginger Krieg Dosier detailed how their process for creating biologically controlled structural cement reduces CO2 production while using existing infrastructure in a model, not unlike the use of ethanol in diesel fuel.

Eben Bayer, the co-founder of Ecovative, debuted the release of 3 new mycelia GIY (grow it yourself) kits and a new mycelium textile. Amy Congdon, a senior materials designer of Modern Meadow, presented on constructing of Zoa™, the world’s first bioleather brand. Created from yeast that had been engineered to produce collagen, the material is practically indistinguishable from its derived animal cousin.

The consumer landscape is changing, and consumers are demanding cleaner energies and sustainable materials, so having a bio-strategy seems to be imperative for companies that would like to shape the future. In the fifth and final session, Strategy: growing the future, Karl Schmieder, founder of MessagingLAB and co-author of ‘What’s Your bio Strategy?

Miroslava Duma, founder of Future Tech Lab, gave insights into the importance of having a biostrategy and how to connect sustainable technologies and innovations. Finally, Dan Widmaier, co-founder of Bolt Threads, described how his company engineers yeast to create an extrudable powder that can be woven into spools of synthetic silk fibres.

Our everyday life has always been surrounded by materials since the Stone Age. Bronze, iron, steel, copper, silk or cotton have been used for millennia to manufacture tools and clothing. However, the demand for consumers and environmental issues like the raw materials on the planet Earth are finite plus the development of biotechnology techniques in the early ’90s have driven new materials challenges.

One of the challenges that designers, engineers, and scientists face is changing the consumers’ perception of these new materials. Biofabricate, the annual summit for the emerging world of grown materials, is the place to be to understand better that, in a not-too-distant future, we will use materials found in nature and materials grown in laboratories.