Interview by Sebastian Kamau

Architect and Bio-practitioner Laia Mogas-Soldevila is at the forefront of developing tools that incorporate biology into the fabrication process. Her research studio, DumoLab*, a collaborative effort with Jorge Duró, uses and develops tools for studying structure and process in product design. Their work draws on the allied fields of mechanical engineering, computation, biology, and materials science to ideate for the Anthropocene.

A consistent theme across their work is a sincere consideration of the environment, both in terms of the conditions within which the manufacturing process occurs as well as the additive network that gives form to an ecosystem. This methodology is informed in large part by Dr Neri Oxman’s theory of Material Ecology, or “study and design of products and processes integrating environmentally aware computational form-generation and digital fabrication. It should then not come as a surprise that both Laia and Jorge were both Research Assistants in Dr Oxman’s research group at the MIT Media Lab.

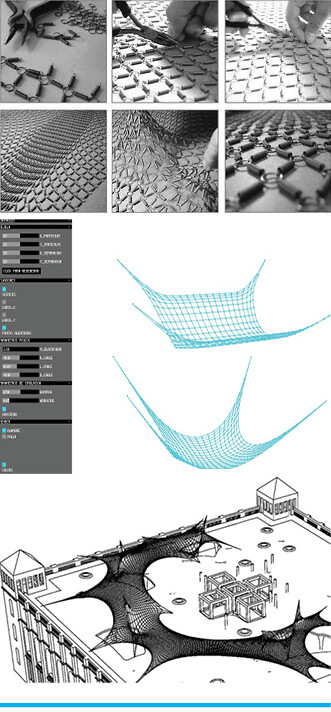

While in Dr Oxman’s group, they helped to develop the Water-based Digital Fabrication Platform (2014-2015), a workflow that uses computational design to both hierarchical structure and 3D print biomaterials. At the heart of this platform is the idea that the process should be prioritised over the product and the flow prioritized over the form. This results in biodegradable structures that give hope to a future of sustainable manufacturing.

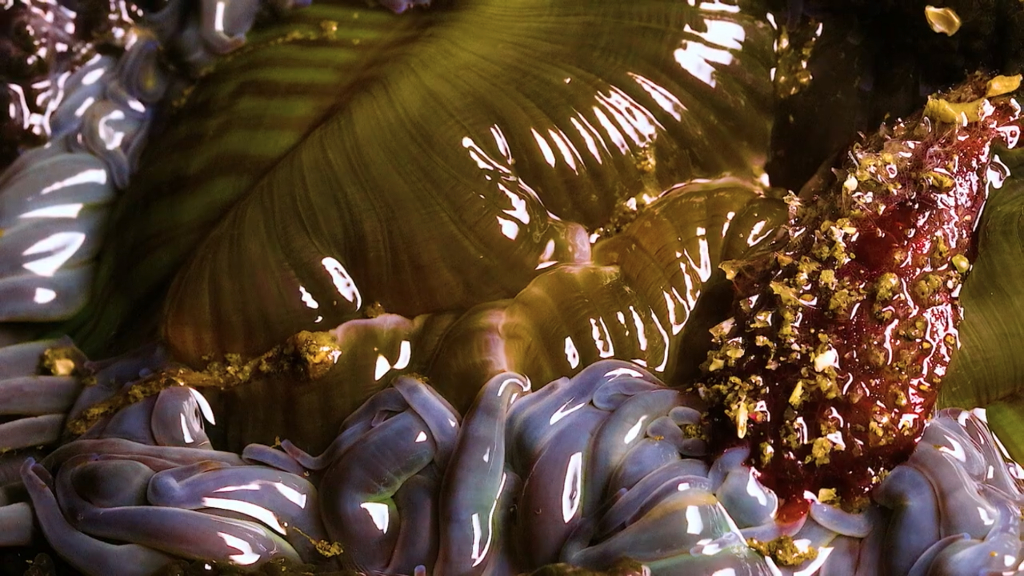

A key aspect of the Water-based Digital Fabrication Platform is a robotic arm affixed with a multiple syringe to extrude water-based composites. Focusing on chitosan, a natural polymer typically found in insect and crustacean exoskeletons, they were part of an interdisciplinary team of biologists, material scientists and mechanical engineers to investigate and print large-scale structures using the platform with venation patterns, similar to those in dragonfly wings and Acer leaves. With possible applications in the fields of architecture, in forms like cantilevers, or biomedicine, as in tissue or cell scaffolds, tools like these broaden the scope of what can be responsibly designed and created.

Laia is continuing to advance the field of biomaterial architectures as a Doctoral Researcher at the SilkLab at Tufts University, led by Dr Fiorenzo Omenetto. As our society becomes more aware of the ecological impacts of current wasteful industrial practices, there is a growing need for practitioners like Laia, who are deeply committed to dreaming and manifesting change.

For those that are not familiar with your work, could you tell us a little bit about the intellectual process behind DumoLab*? What drew you to work at the intersection of biomaterials, technology and life sciences?

My partner Jorge Duró and I started DumoLab in Barcelona around 2008 as an experimental self-directed practice to explore computational design and new material systems. We moved to MIT in 2011 and developed work with incredible people such as Mark Goulthorpe at the MIT Large-scale Robotics Manufacturing Lab and Meejin Yoon and Eric Howeler’s at MYStudio. We also worked with Christine Ortiz’s Structural Biological Materials group, which got us interested in strategies for the deeper inclusion of material science and biology in the design practice.

This led us to meet Neri Oxman and join her Mediated Matter group at the MIT MediaLab, where we worked on a novel Water-based Fabrication Platform with biologists and physicists to integrate organismic and material performance into digital design and fabrication. Today as a Doctoral Researcher at the Tufts BME SilkLab led by Fiorenzo Omenetto, I am a very privileged Architect immersed in a state-of-the-art Biomedical Engineering environment bringing bio-material exploration forward into sustainable products and architectural parts.

BIOFABRICATE is the annual summit for the emerging world of grown materials held in New York City in November. What impact do you think the conference will have on the future of materials?

Lately, Designers and Architects in both practice and academia are making an effort to reach out to scientists and develop a rigorous curriculum on the possibilities of incorporating bio-materials and biology into products with the potential to revolutionize industry.

BIOFABRICATE is a key gathering for their voices to be heard and to set a sharing platform towards a new era for products and ideas at the intersection of design and biology. What technical invention do you think will have more social acceptance or impact in real life in the not-too-distant future?

We are still not used to welcoming synthetic biology into the daily life of products. However, inventions that harness the benefits of bio-derived or regenerated bio-materials – those are materials naturally produced by organisms – have a higher potential to set the path towards a more bio-based and sustainable product design and fabrication industry.

What direction do you see taking your work at DumoLab* into?

Jorge and I are extremely grateful for all of the mentioned research opportunities, and we see them nourishing DumoLab* and pushing the studio forward into uncharted territories for a design where there is no distinction between material system and design form-finding, where materiality and its deep and rich information is fully incorporated into digital design workflows.

What is your chief challenge of creativity?

The main challenge to innovative creation today in architecture and product design is the difficulty of integrating the physical world into the rigid CAD tools that we use. Research in this direction fascinates Jorge and I, and we have explored it in our MIT theses entitled “New Design Companions” and “Fabrication Information Modeling”.

You couldn’t live without…

Research! At this point, having spent 5 years at MIT Architecture and starting new bio adventures at Tufts Biomedical, we realize that our design aims at DumoLab* could not evolve without the deep research platforms, the highly generous scientific community, and immense opportunities that these environments provide.